Efe Kiraz’s testimony about the « Laser World Of Photonics » held in Munich (June 2025)

This laser fair was a motivating event for me because I have had the idea to understand fundamentals of the nature and be able to apply phenomena to engineer different systems since I graduated from university. At the fair, I had the opportunity to observe how physics is harnessed to design and manufacture these cutting-edge technology products. Moreover, I would like to thank Edmund Optics for sponsoring our tickets to the fair.

Before the event, I was planning to visit photonic integrated circuit companies. In addition to this plan, I came across with more complex realized system and I didn’t miss the chance to ask questions about it.

The first company was focused on glass processing, they basically designed self-cleaning surfaces. They process the uppermost layer, which interacts with the atmosphere, of solar cells so that the surface becomes dust-repellent. This product is deployed in desert-like environments as a green energy source. The company has also patented some of its surface processing patterns.

I also visited some of the Fraunhofer Institute booths at the fair. Some of the designs and design ideas really drew my attention, and I would like to mention them in detail.

Fraunhofer ILT

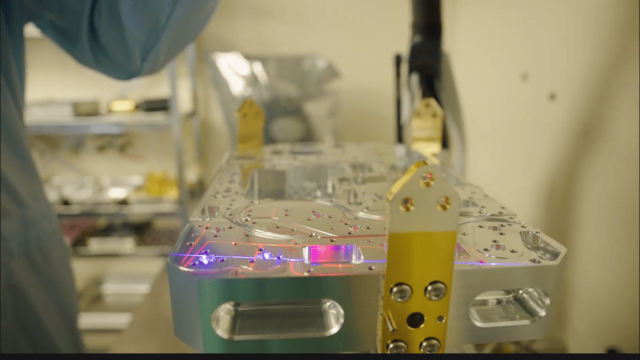

I got the chance to observe Spaceborn LIDAR. The designed LIDAR system provides information about constituents in our atmosphere, for instance, methane (CH4) gas density measurement. In the project MERLIN (Methane Remote Sensing Lidar Mission), no adhesive material is used; this demonstrates the ultra-stable mounting technology of ILT. The reason is not using adhesives is to achieve, in spite of thermal and mechanical shocks in the atmosphere, 6-7 years of planned operation time. Dr. Ing Heinrich Faidel has explained to us the system whose parts are seen in figures 1 and 2 below.

Figure 1: Body of the structure

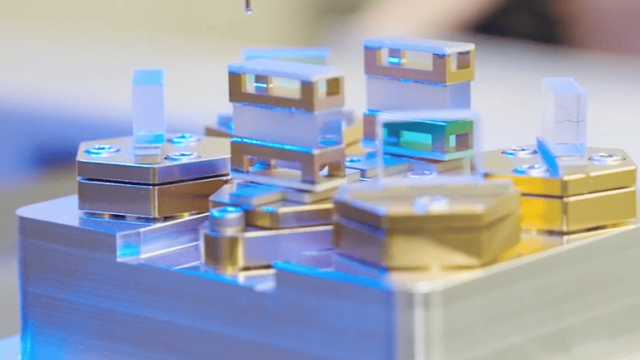

As it can be seen from Figure 2, optomechanical components are mounted with screws and bolts. This property of the system is highlighted several times during his speech, I think it is a very critical property that a spaceborne system must have.

Figure 2: Optomechanical components placed onto body of the structure

Mounting with bolts and screws will cause an increase in system weight. It is not seen on the figures but the inner parts of the structure body have weight reduction cutouts and this gives a grid-like or mesh-like pattern throughout the body of the structure. I believe processing metallic structures by keeping in mind optical and electrical constraints is quite cumbersome.

Fraunhofer IPMS

In this booth, I had the opportunity to observe microelectromechanical systems (MEMS). These units can be integrated in photonics integrated circuits, for example, phase tuning in interferometers. In my master’s thesis, I am working on Mach Zehnder Interferometer-based electro-optic modulators on thin-film lithium niobate. I am tuning the phase of the interferometer by microwave frequency electrical field. As for the MEMS, they tune the phase by external physical effect for example, pressure.

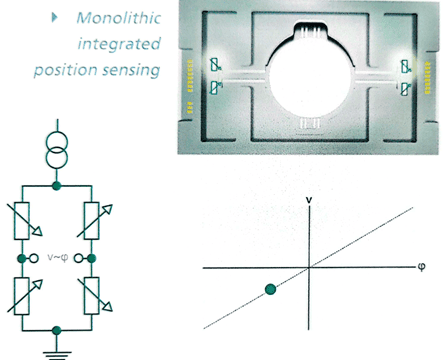

Figure 3: MEMS scanner piezoresistive deflection sensing and its read-out circuit. “MEMS mirrors-resonant and non-resonant optical scanners with integrated deflection sensors”, Fraunhofer IPMS

In Figure 3, a monolithic integrated MEMS position sensing unit is seen. The four resistors are placed next to torsion springs similar to a Wheatstone bridge, which helps suppress temperature-dependent changes. These units can be used in LIDAR applications, beam positioning and scanning

Finally, Latifah Amber Maasarani has introduced some of the new products in Edmund Optics. One of them is Coherent® High Performance OBIS™ LX/LS Laser System, which is a plug-and-play laser for a wide range of wavelengths from UV to NIR. Then, they offered coffee and some snacks in addition to souvenirs.

Efe Kiraz – EMIMEP student